Existing customer? Login

Interview

January 5th, 2023

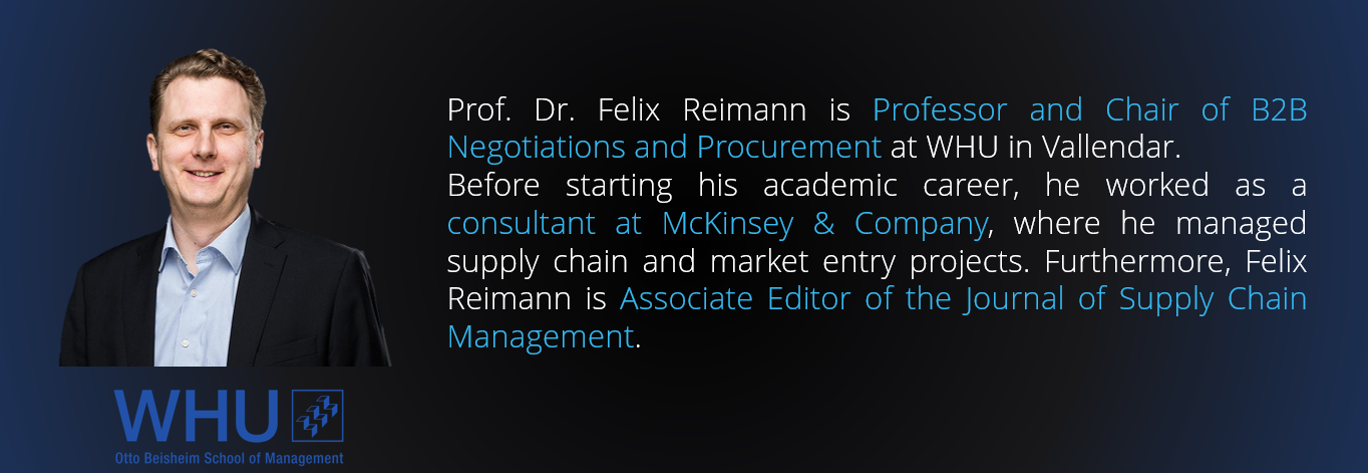

Interview with Prof. Dr. Felix Reimann, WHU

Eros Vecchio

Eros Vecchio

Managing digitization, reducing CO₂ emissions, recruiting talent - procurement is currently facing various challenges. Together with Prof. Dr. Felix Reimann from WHU, we take a look at these very trends in procurement and also ask the question: What role does procurement actually play at elite universities like WHU?

More information about the person

Professor Reimann, you head a chair at WHU in Vallendar that deals specifically with procurement. That's something special, isn't it?

So, to be quite precise, I am a professor of B2B Negotiations and Procurement at WHU, making me one of two procurement chairs; and that is quite special. At WHU, I research and teach about negotiations in procurement, in particular how negotiations between buyers and suppliers proceed under real behavioral aspects. After all, we humans are not rational machines, but aspects such as trust or personalities also have a major influence on the outcome of cooperation. And I currently pass on this knowledge to students in all WHU programs, from the Bachelor to the MBA, in my courses.

So what recent results from your research can you share with us?

In our last project, we addressed the question: When I negotiate with suppliers, how do I actually conduct this negotiation best? Should I focus more on presenting the advantages of the project to the supplier? Or should I rather communicate my own expectations very clearly? And just casually asking that, most people have a sort of natural preference here: for some, negotiations are basically a sort of tug-of-war where they "go in hard." And then there are others who see a negotiation more as a collaborative value creation process.

What we have found out, however, is that it depends very much on the situation. It is by no means the case that one or the other variant is always good. Instead, it depends very much on the given power constellations. If, for example, the supplier is in the driver's seat, a collaborative approach is a way to go for better negotiation results. But if I have balanced negotiating power or am even a bit stronger myself, then this approach tends to be counterproductive because I then confuse the other side or make them suspicious. In this case, the supplier tends to expect me to enter the negotiation with a certain authority and react better accordingly.

These are indeed very exciting insights. In your opinion, what are the advantages of giving young students this kind of knowledge about procurement as early as possible?

So I would say that we simply give the topic of procurement and negotiations the appropriate importance. If you take a look at an industrial company, procurement costs often account for 50% of sales. And for many large companies, especially in the consumer goods and automotive sectors, the figure is as high as 70%. Let's take a bottle of shower gel. The manufacturer receives one euro for the sale of this bottle, of which 70 cents go directly to the suppliers. If one considers now times that there are numerous BWL courses of studies, where the whole topic procurement does not occur at all, then that is nevertheless absurd. After all, purchasing is a huge part of my value creation.

What else do you think speaks in favor of stronger education in purchasing?

I think that in recent years we have seen very clearly that the greatest operational risks lie in the supply chain. The upheavals caused by the war in Ukraine, but also lockdowns in China or the blockade of sea routes; all of these can quickly have catastrophic consequences. And if I don't manage this adequately and don't have transparency in my company, I'm screwed. Then there's the whole issue of sustainability and my company's CO₂ footprint. For most companies, apart from heavy industry, the big lever in this area is the supply chain, which is often located abroad and is therefore not properly recorded. But if I'm serious about reducing my footprint, then I also have to keep an eye on my supply chain. And for that, I need maximum transparency.

You're talking here about the different scopes through which CO₂ emissions can be measured, right?

Exactly. Scope one refers to emissions from the company's own operations, scope two to energy requirements, and scope three to the supply chain. Incidentally, a new law came into force in Germany this year that obliges large companies with more than 3,000 employees to systematically address the social and environmental aspects of their own suppliers. This German law is, I would say, still relatively manageable for companies. At the same time, however, a law is on the way at the EU level that will be even more demanding. And this means that companies must now take action. Otherwise, they will be exposed to considerable financial risks.

There are certainly not too many students at WHU who are looking for a career in procurement right from the start. How is the whole topic of procurement and negotiations received by your students?

It is indeed the case that many students first come to the first course with a question mark and think to themselves: Is this topic that interests me here? But the nice thing is that this changes relatively quickly. By the way, this is also because the idea of purchasing before the event is a very administrative one. And this idea is, of course, fundamentally wrong and in part highly dangerous.

By the way, our goal in training is not that all our students end up in the purchasing department at the end of the day. Rather, we try to create a fundamental understanding of the function and value levers of purchasing. Because even as a CFO, you will inevitably come into contact with purchasing. Not least because in companies this is often hung up under the CFO.

Let's move on to digital solutions in procurement. In your view, what role do they play in the modern purchasing world?

In my view, the whole topic of digitization is a necessary development that will become much more important in the future. Of course, there are already really excellent digital solutions and systems today, but there will certainly be a lot of further development. Unfortunately, it is also the case that in many companies the current system landscape in purchasing is still neither particularly good nor particularly powerful. As a result, even relatively simple questions in purchasing are difficult to answer, such as: Who are actually our biggest suppliers, measured by the money we spend with them? Or from which countries do our materials actually come?

But great progress is currently being made in this area as well, particularly with regard to the availability of data and attention to data. And once I have this transparency, I can of course optimize my purchasing in a completely different way. For example, I can see where there are anomalies or deviating prices, or where there are risks in the supply chain. And all of this is only made possible by having this new, modern system landscape..

But what do you think is the reason why the system landscape in Germany is still lagging so far behind?

On the one hand, this is due to the fact that you simply have systems that have grown organically over time, which are poorly integrated and in some cases also poorly maintained. In some cases, you have data records where the same supplier can be found in the system under five different names. But it's also because some companies have invested too little in purchasing over the years, both in terms of personnel and digital solutions. They simply thought it would work out that way. Due to the strong risks recently, this is changing noticeably right now, but of course, a long-term development must also be recognizable. Not just now, when there's a fire.

Now you have already mentioned the keyword personnel. Do you actually have the feeling that there is a lack of good, perhaps also digitally affine junior staff in purchasing?

Of course, there are companies that have enormously good people in purchasing. But there are also companies that find this difficult. And it is certainly the case that young, highly qualified IT experts are not the first to think: I'm going to work in the purchasing department of a medium-sized German company, that's perfectly clear. At this point, purchasing and the entire environment simply have to become more attractive, and part of that can and must be more digital solutions.

But simply using digital solutions won't be enough, will it? The staff must also know how to use the software.

Absolutely. Otherwise, I'm at the mercy of the software, so to speak. All the data in purchasing also has to be used correctly, so a lot of investment has to be made here; kkeywordsare training and education. But as I mentioned before, when I consider that a good 50% of my sales are spent on delivery costs, this is perhaps also an area where the investment is more than worthwhile.

Does the management of German SME's see it that way, too?

When you talk to managers who are currently making a turnaround because the company is doing badly financially, you often hear one thing: I have to cut staff everywhere; there is only one department where staff is currently being increased - and that is purchasing. Because they recoup many times over what I pay them through good negotiations with suppliers. And they do so immediately.

What trends and developments are you currently observing in procurement, with the exception of digitization?

Right now, risk management is something that overlays a lot of things. There's no getting around that right now. And in the longer term, we see the issue of sustainability, especially CO₂ avoidance, as something that will gain enormous importance and attention. The expectation is generally that in the future we will also be less and less able in the supply chain to simply produce CO₂, but that these emissions will be increasingly associated with costs. So I have to be able to address this problem already in the foreseeable future.

Do you think the companies concerned are actually sufficiently equipped for this new challenge?

It varies; I really do see a great deal of heterogeneity in the given conditions. The core problem is that many companies have systematically underinvested in their purchasing capabilities for a long time. And if this law is now an impetus to look at whether my purchasing even meets my expectations, then that can be a real benefit for many companies. Because if I don't know who my suppliers are, that's always a huge risk. Not only in terms of working conditions and the environment but also in terms of the vulnerability of my supply chain.

You would like to know how SCALUE could help to optimize your procurement?

Last but not least: Do you have any hands-on tips for our readers on how to optimize their purchasing departments?

So I would really strongly recommend to the management to make purchasing a top priority; and not only when the store is on fire. This can start by simply going to the purchasing department and asking questions: Who are our most important suppliers? From which countries do we purchase which goods? Which suppliers pose the greatest risks? Which suppliers have the greatest potential for innovation, and how do we exploit this? If this question cannot be answered, I have to change something immediately in order to remain competitive.

Another thing that can also be really enlightening is to ask self-critically: What reputation does my purchasing department actually have in other areas of the company? Are we seen there as an economic driver or rather as a bureaucratic stumbling block in the implementation of a project? If you answer these questions honestly and optimize processes accordingly, purchasing can become a valuable player in a very short time.

How SCALUE can help you? Schedule a free demo now!

Learn more on our blog: Get More Insights

Follow us on LinkedIn: Get more Content