Existing customer? Login

Interview

January 13th, 2023

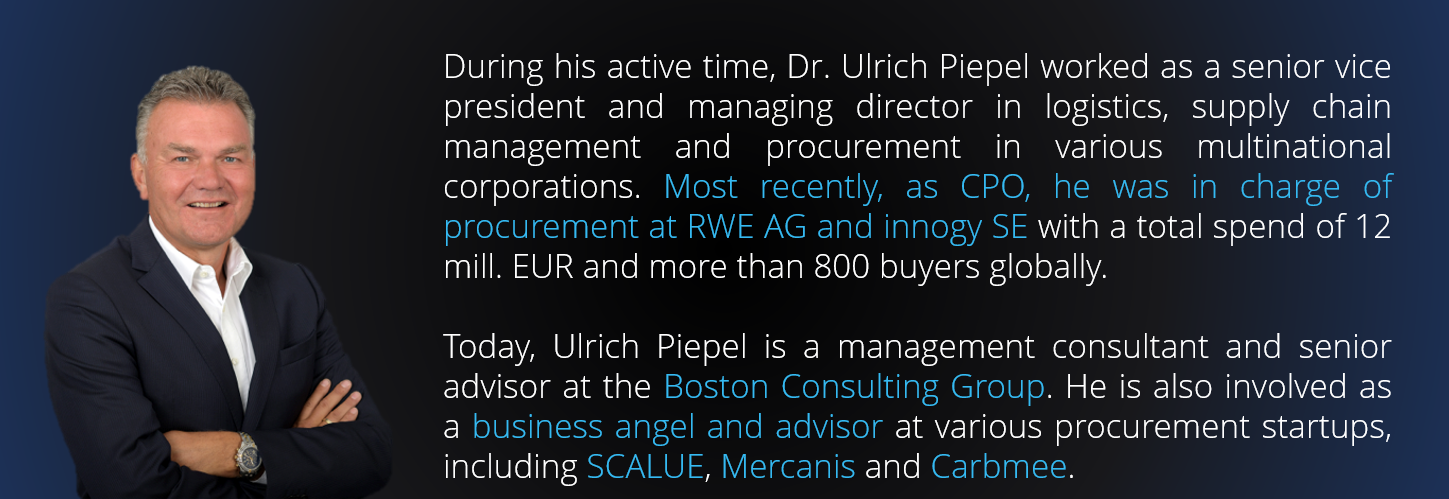

Interview with Dr. Ulrich Piepel - Part 2

Thomas Teichmann

Thomas Teichmann

Maverick buying still poses major problems for many procurement departments today - and mostly unnoticed. We talked with Dr. Ulrich Piepel, former CPO of RWE AG and innogy SE and today consultant and business angel for digital procurement, about his view of "wild procurement". He also gives us deep insights into his time as head of procurement (CPO) for several large corporations and dares to take look with us a at the future megatrends in the industry.

More information about this person

In the first part of the interview, we talked to Dr. Ulrich Piepel about how Maverick Buying can also affect the reputation of purchasing within a company. Now we would like to know how this can look in practice and how it can be counteracted.

You haven't read the first part of the interview yet?

Do you have a practical example for us at this point?

I can well remember that in the past, for example, that procurement of legal advice or business consulting was handled by various departments and thus was not part of the procurement volume. I then managed to persuade the Board of Management to transfer this responsibility for these two product groups to procurement as well. When procurement took over and then negotiated with legal or management consultancies, we were sometimes not taken seriously at all. Simply because these consultants knew: what procurement is putting in the framework agreement is meaningless anyway; we will negotiate that later with the Management Board or with the management ourselves without involving procurement. Only through clear rules within the procurement guideline and the professional development of a specialized procurement team for these two categories were we able to solve this task successfully and eventually also generally accepted with in the corporation.

How did you approach this problem? Do you have any practical advice?

One of my first activities as CPO always has been the introduction of a company-wide procurement guideline. This was drawn up by procurement in cooperation and coordination with the corporate organization department and then approved and signed by the Management Board. This guideline was valid for all departments and employees in the company and not just for procurement. This means that from that point on we had a regulatory framework in procurement that we could relate to all departments in the company. This helped us to reduce maverick buying to almost zero, showing individual people that they are violating group wide instructions and thus playing with their job.

At this point it would be time for a police comparison again, wouldn't it?

But only because it fits so well at this point. Let's say the police checks whether all drivers obey the speed limit. At the same time, however, if police has no regulatory framework, i.e. no traffic regulations. Then no fine can be imposed or no action can be taken and everyone drives as fast as they want. That was exactly what happened when we measured ‘Maverick Buying’ in the company without having a valid procurement policy. You can uncover it, but there is no regulation within the company.

What would you say to the thesis that the CPO in a company should be at least on an equal footing with the CFO or the COO?

In most companies 50, 60 or 70% of all total costs or even more are attributable to procurement spend. Accordingly, the CPO has an extremely important task with a very high leverage for the profit and success of the corporation. And such an important and complex function must also be classified hierarchically on top level. So, either directly on management board, or highly exposed with a reporting line to the CEO. As a CPO with its diverse and many challenges, every company needs a CEO or a management board which clearly formulates: there are crucial central functions in our company such as procurement and therefore all departments must work together with procurement accordingly.

In your opinion, should procurement always be centralized?

In my view, procurement is a function that should always be centralized organizationally, but not geographically. The reasons for this way of organization are manifold: numerous benchmarks and studies, performed also by renowned by management consultancies, show that centrally organized procurement organizations with a companywide solid line reporting can demonstrate a significantly higher performance. However, based on my experience there will be always discussions with the relevant country or regional managers, even if this centralized procurement organization shows are very high performance. A statement that is often made by the managing directors of a national subsidiary is: “I am responsible for EBIT, so I must also be responsible for procurement.”

However, these managers often forget that a well-established and central organization of procurement will bring significantly better results for the national subsidiary as well. Therefore, every company needs a strong procurement department with a strong CPO, who in many cases should also be part of the management board. In the automotive industry or in retail, for example, this is very often the case, because in these industries 80 to 95% of the company's total costs are attributable to procurement. But even with lower percentages, such a central organization makes much more than sense.

Finally, let's take a look into the future: Which trends and developments do you currently see as particularly relevant in procurement?

There are currently a large number of megatrends in procurement. The first megatrend is, of course, that procurement - as almost all functions - is becoming more and more digitized. And in the transactional and operational procurement processes, for example, there is a wealth of transactions that can and must be automated or digitized. These include tenders, negotiations, electronic auctions, order processing, data exchange with suppliers, accounting, etc. These topics are not new, but they have not yet been implemented consistently and companywide in many cases, including large corporations.

For example, I know large corporations that only recently introduced electronic signatures, since in times of Covid-19 the employees were now working from home. Everybody can imagine the gigantic manual effort required in procurement for hundreds of thousands of signatures, which have to be done for all orders and framework agreements. Now imagine the enormous potential which can be unlocked when even more complex processes in procurement are finally fully digitized. Here many CPO’s have made not enough progress in recent years.

The digitization of procurement is of course on everyone's lips. Apart from that, which megatrends will determine the next few years?

The whole issue of CO₂ measurement is at least as important as digitization. This topic is specifically about Scope 3 emissions, i.e. every carbon molecule that is generated within the supply chain, for example through transport, manufacturing products or other performing services. For example, the SEC (US Securities and Exchange Commission) has stipulated that all S&P 500 companies must measure and disclose all Scope 3 emissions since January 1st, 2023! And who, apart from procurement, should measure and mitigate this? The Chief Sustainability Officer certainly can't do that because, because that is something which is determined or decided at the operational procurement level. Of course, this also requires new software solutions. With this important task for humanity, I am supporting the start-up Carbmee, which discloses exactly these emissions in the supply chain and reduces them in cooperation with all company's suppliers.

Why will it be so important in the future to disclose CO₂ emissions in the supply chain?

In my opinion, avoiding CO₂ emissions in the supply chain will become the fourth dimension of procurement. Of course, this is primarily related to the increasingly expensive CO₂ certificates that have to be purchased to offset the CO₂ emissions generated. And even if it is not your own company that causes the emissions, but the supplier, your own company still indirectly pays the price for the CO₂ certificates. In addition, every company must of course also develop ecological and sustainable acceptance among all customers in order not to endanger or even expand sales. This important connection should not be neglected in today’s world.

In this respect, procurement should definitely be able to measure the Scope 3 emissions; not least because on average approx. 85% of all emissions are created in the supply chain. However, the many procurement departments have so far hardly dealt with this topic and have not built up any knowledge about it. Besides knowledge about prices, delivery times or product qualities procurement must quickly build up their knowledge about CO₂ emissions and their costs.

All right, we have digitization and measurement of CO₂ emissions in the supply chain. Are there other megatrends on the horizon?

In my opinion, another megatrend is the topic of ESG (environmental, social, corporate governance). ESG is currently being discussed in many countries and laws are being enacted, such as the German Supply Chain Due Diligence Act. The same is currently happening at European level. But the measurement and evaluation of the ESG criteria is even more complex in many areas than is the case with CO₂ emissions. For example, how do you measure child labor or environmental damage caused by suppliers in the supply chain? In any case, we will not be able to avoid this important topic, especially since banks, investors and rating agencies no longer only assess companies according to their creditworthiness, but also according to ESG criteria. Accordingly, procurement also has to deal with this in the short term.

But there is also help for procurement, such as the Slave-Free Alliance. As the name suggests, this company deals with the issue of slavery in the supply chain and looks at what exactly happens in other countries at the fourth or fifth stage of supply. The old adage “out of sight, out of mind” no longer applies.

Those were super important points. But I can also see that there is a topic that is still burning under your fingers. Which one is this?

We all have a common problem in Europe and in many other industrialized countries, and that is the problem of demography. In the years and decades to come we will have too few staff for the diverse tasks of the future. Many are now saying: Yes, this can be solved with immigration, but this must also be structured. Because uncontrolled immigration does not mean that all companies get the employees they need for the complex tasks of the future. And the question may be asked as to whether Germany is still attractive enough for talents from all over the world in terms of modern and efficient administration, tax legislation, infrastructure, security and much more.

So now we really come to the last question: What practical tips do you have for all procurement managers out there so that they can make 2023 successful?

Success often comes from bold and groundbreaking decisions. And in some companies, procurement is simply too hesitant, too slow and not very courageous. Perhaps it is because procurement in many companies simply lacks appreciation. For example, if sales generate 20% more revenue, the CEO and CFO will celebrate this company-wide. But if procurement saves about 3% in costs - and this has about the same effect on corporate profit as 20% more sales, nobody really notices. In my opinion, there needs to be a completely different self-image and awareness, and this must primarily be exemplified by the procurement managers.

Another example: I know quite a few CPOs who find it very difficult to introduce software from a startup or a digitization solution like SCALUE. But because of its high complexity and diversity, procurement requires a large number of different digitization solutions, but these are used much too slowly and hesitantly, if at all. The CPO often boasts that he is responsible for a large procurement volume of two, five or ten billion euros, but he does not manage to fight for a budget of lets say €50,000 for a digital solution in procurement; and that although these costs are a low number fraction compared to the procurement volume. In addition, future challenges in procurement can only be mastered with digital solutions. And this inevitably goes hand in hand with the importance of procurement.

You would like to know how SCALUE could help to optimize your procurement?

So success in procurement is difficult to achieve without courage?

Definitely, after all, you usually recoup the costs of an investment in procurement in no time at all. In many cases, the return on investment is not years, but months or weeks. My appeal at this point is therefore: As a procurement manager, have the courage to make such investments and break new ground in the areas of digitization, human resources, organization and responsibility. If you are a procurement manager and you are anxious and want to please everyone, then you will never make any progress. And if you want to be the most popular colleague as a procurement manager, you are quite simply in the wrong position. As simple as that.

How SCALUE can help you? Schedule a free demo now!

Learn more on our blog: Get More Insights

Follow us on LinkedIn: Get more Content